Who We Are

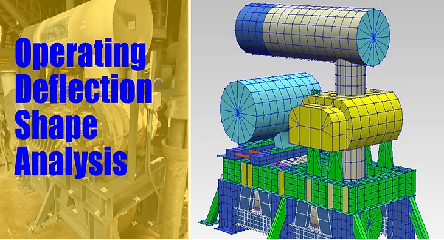

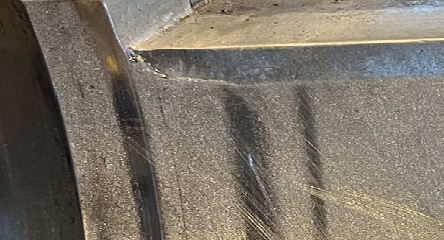

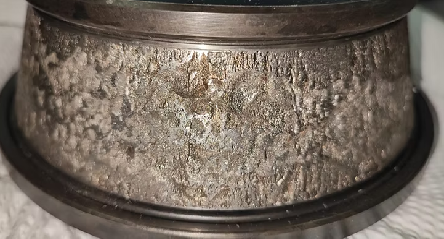

Machinosis Company Limited (MCL) is an independent consulting company who can provide one-stop services and total solution for machinery condition monitoring and diagnosis. We are capable to deliver wide range of services with extensive and highly experienced in servicing all kinds of machinery in process plants.

Machinery condition can be assessed correctly and effectively using various condition monitoring technologies, tools, and disciplines, therefore, unplanned maintenance or forced outage can be avoided to prevent production lost while increasing reliability and availability.

Learn more at https://www.machinosis.com/

We’re paving the way for AI-enabled predictive functionalities, integrating data acquisition, and leveraging analytics. This fusion of technology and innovation empowers maintenance teams, driving them to operate smarter, faster, and more effectively than ever before.