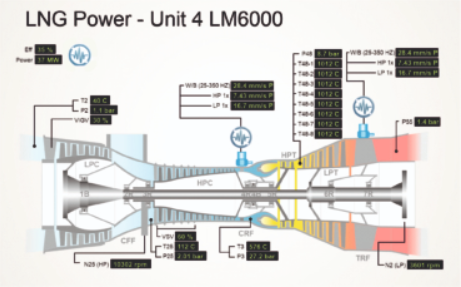

Bruel and Kjaer Vibro is the leading worldwide independent supplier of machine protection and condition monitoring solutions for rotating and reciprocating critical and balance-of-plant machinery. The comprehensive end-to-end solutions include vibration sensors (acceleration, velocity, and displacement), rack-based plant-wide integrated monitoring solutions, easy-to-use software, vibration monitors, and handhelds. B&K Vibro provides condition monitoring as part of predictive maintenance strategies with the unique ability to integrate with an existing or new AVEVA™ PI System™ seamlessly. B&K Vibro solutions can deliver a comprehensive view of past and current data to identify potential faults before they occur. A suite of comprehensive services to fulfill the most demanding applications for safety, condition, and performance monitoring of rotating and reciprocating machinery complement these robust solutions.

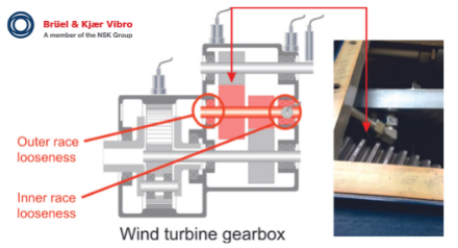

B&K Vibro brings 80 years of experience in vibration monitoring to successfully give real-time and accurate data to reduce downtime and maintenance costs while simultaneously increasing machine reliability and preventing critical machine failures for customers worldwide. B&K Vibro provides solutions for many industries, such as Oil & Gas (upstream, midstream, and downstream), Wind, Pulp & Paper, Mining, and more.

Application list:

- Condition Monitoring

- Machine Protection

- Diagnostics

- Online Monitoring

- Offline Monitoring

- Continuous Monitoring

- Semi-continuous Monitoring

- Critical Machine Monitoring

- Balance-of-plant Machine Monitoring

- Machine Protection

Industries:

- Oil & Gas

- Pulp & Paper

- Wind Power

- Mining

- Metals

- Pharmaceuticals & Chemicals

- Thermal Power

- Petro-Chemicals

- Cement

- Hydropower

- Machine Tools

Stay connected with the leading worldwide independent supplier of condition-monitoring solutions for rotating machinery!

Receive regular updates and a monthly newsletter from Brüel & Kjær Vibro.